Central Steel Supply Company supplies metal form decking used in structural floor and roof assemblies through trusted partner sources, allowing consistent availability while supporting a one‑stop material procurement experience. These profiles support concrete placement, slab reinforcement, and general deck formwork requirements through reliable partner‑supplied availability while enabling fabricators and contractors to maintain efficiency in both shop and jobsite workflows.

The following sections outline available deck types, dimensional elements, and coordinated sourcing options for a complete material solution.

Types of Metal Decking

Floor Decking (Composite & Non-composite)

Floor decking functions as a permanent form for concrete placement and may be used in composite or non-composite applications depending on the project design.

- Composite Floor Decking

- Composite floor decking includes embossments in the rib webs. These indentations enhance the mechanical interlock between the concrete and the steel deck, enabling both materials to work together as part of a composite slab rather than acting independently.

- Composite deck is used when the project’s engineering design calls for the steel deck and concrete slab to function together as a structural system. When composite action is not part of the design intent, non-composite or form deck serves as an efficient and cost-effective solution that supports concrete placement without the added expense of composite features.

- Non-Composite Floor Decking (Form Deck)

- Non-composite, or form deck, features smooth rib webs without embossments. This design allows the deck to function solely as a permanent form for concrete placement, with the concrete and steel deck acting independently rather than working together as a composite system.

- Non-composite, or form deck, is used when the deck’s purpose is to serve as permanent formwork for concrete placement and the slab does not rely on steel–concrete composite action for added strength. In these applications, form deck provides reliable, cost-effective support for the concrete without the additional features associated with composite profiles, simplifying installation and meeting project requirements with an efficient, purpose-driven design.

Roof Decking

Roof decking supports insulation, roofing membranes, and the mechanical loads associated with roof structures, forming a stable substrate for the complete roofing assembly. Profile selection is based on rib width and depth, as these characteristics influence spanning behavior, diaphragm performance, attachment methods, and compatibility with different insulation and roofing systems. Deeper or wider rib profiles are commonly used where increased rigidity or greater spacing between supports is part of the overall design intent, while shallower profiles are typically associated with lighter-duty systems or shorter support spacing. Final profile selection follows the requirements established by the project’s engineering team as part of the overall roof system design.

Common roof deck classifications:

- B Deck (WR — Wide Rib)

- F Deck (IR — Intermediate Rib)

- A Deck (NR — Narrow Rib)

- N Deck (DR — 3″ Deep Rib)

Since roof deck is not intended to support concrete or participate in composite action, it is manufactured with smooth ribs and no embossments.

Dimensions, Grades, and Value-Added Support

Metal decking is identified by its rib geometry and key dimensional features, which define the profile’s functional characteristics. Central Steel Supply Company assists in connecting customers with the specific decking profiles identified in the project’s engineering documents, ensuring the required materials are sourced accurately.

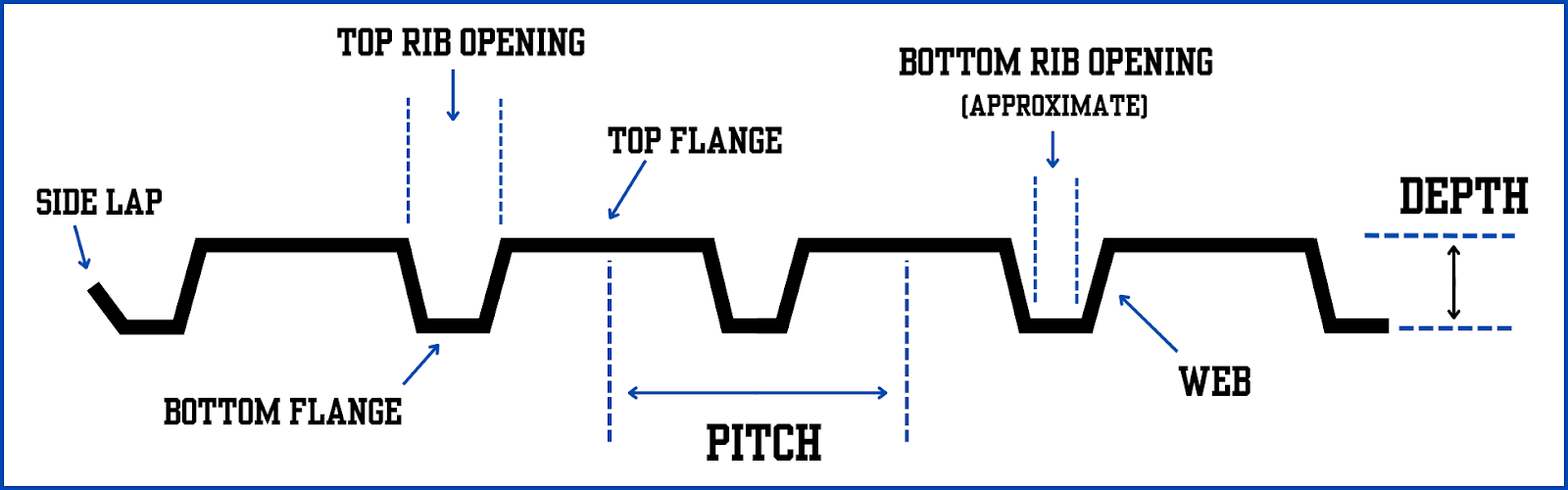

The profile diagram below corresponds with the standard terminology used throughout the industry.

Primary dimensional components include:

- Top Flange: Flat surface at the top of the rib.

- Web: Vertical or sloped surface connecting the top and bottom flanges.

- Bottom Flange: Base surface of the rib.

- Top Rib Opening: Width between the top flanges of adjacent ribs.

- Bottom Rib Opening: Width between bottom flanges of adjacent ribs.

- Side Lap: Interlocking connection between sheets.

- Typical connection types include:

- Nested Side-Lap

- Interlocking Side-Lap

- Interlocking Side-Lap for Screw Connections

- Typical connection types include:

- Pitch: Center-to-center spacing between ribs.

- Depth: Overall rib height.

Thicknesses & Depths

Floor Deck

- Composite:

- Thicknesses: 22 gauge (0.030”) – 16 gauge (0.060”)

- Depths: 1-1/2”, 2”, 3”

- Non-Composite (Floor Form Deck)

- Thicknesses: 26 gauge (0.018”) – 18 gauge (0.048”)

- Common Depths: 9/16”, 1”,1-1/2”

Roof Decking (Roof Form Deck):

- Thicknesses: 22 gauge (0.030”) – 16 gauge (0.060”)

- Rib Depths:

- A-Deck: 1-1/2″ narrow rib

- F-Deck: 1-1/2″ intermediate rib

- B-Deck: 1-1/2″ wide rib (most common)

- N-Deck: 3″ deep rib (longer spans/heavier conditions)

Finishes

Decking is available in the following finishes:

- Unpainted

- Painted

- Galvanized

Finish availability varies by profile and thickness.

Typical Grades of Metal Decking

Floor and roof decking are typically manufactured from sheet steel produced to ASTM A653 (galvanized) or ASTM A1008 (uncoated or painted) specifications.

***Please view our Product Catalog for specific detailed dimensions for available Metal Decking ***

Although metal decking is supplied without cutting, shearing, or forming, Central Steel Supply Company supports project efficiency through dependable availability, coordinated sourcing of complementary materials, and assistance in connecting customers with the specific decking profiles identified for the intended floor or roof assembly.

Value-Added Support

Central Steel Supply Company supports efficient project planning and material availability for metal decking by coordinating metal form decking, complementary structural materials, and accessory items through trusted partner sourcing. Although metal decking is supplied without cutting, shearing, or forming, consistent inventory, material expertise, and dependable sourcing help streamline procurement and reduce shop-level interruptions. This approach provides practical value for fabricators who benefit from receiving ready-to-use material while keeping internal labor focused on fabrication, assembly, and onsite installation.

Even without processing services, metal decking is supplied in consistent, industry‑standard lengths and profiles offers practical advantages:

- Predictable handling and staging for fabricators managing high‑volume deck installation.

- Straightforward integration into shop workflows without managing variable deck configurations or field‑cut requirements.

- Uniform profiles that support efficient layout planning, attachment preparation, and productive sequencing of deck placement.

Central Steel Supply Company further enhances project coordination by:

- Offering material-selection insight aligned with general structural intent, while directing customers to the project engineer for load, span, or diaphragm‑related requirements.

- Coordinating complementary items such as structural shapes, plate, or reinforcement products to simplify procurement.

- Supplying consistent, ready‑to‑use material so fabricators can maximize labor efficiency on deck placement, assembly, and jobsite deliverables.

Material-selection guidance is limited to identifying profiles that align with general project intent, and customers should consult the project’s engineer for load, spanning, or other engineered recommendations.

Industries and Common Applications

Floor and roof decking support a wide range of building types and structural assemblies. Typical applications include:

- Commercial Construction: Multi-story buildings, office structures, retail spaces, and mixed-use developments requiring slab or roof deck systems.

- Industrial Facilities: Warehouses, distribution centers, manufacturing plants, and equipment platforms where deck strength and diaphragm performance are part of the building system.

- Institutional Projects: Schools, hospitals, municipal buildings, and public-use structures requiring standardized and repeatable deck profiles.

- Residential & Multi-Unit Housing: Mid-rise and high-rise residential buildings incorporating floor slabs supported by composite or non-composite deck.

- Infrastructure & Public Works: Transit facilities, parking structures, and utility buildings using deck as part of structural floor or roof assemblies.

- Fabrication & Construction Services: Shops and contractors integrating decking into slab formwork systems, building expansions, equipment mezzanines, and general framing assemblies.

Contact Us for a Quote Today

Partnering with a supplier that delivers reliable inventory, precise material accuracy, dependable service, and strong technical expertise helps create lasting business relationships and elevates overall customer success. Central Steel Supply Company provides steel products and value-added services that enhance efficiency, reduce delays, and keep projects moving with consistent productivity. Quotes for material availability and processing options are available upon request.

CONTACT

CONTACT